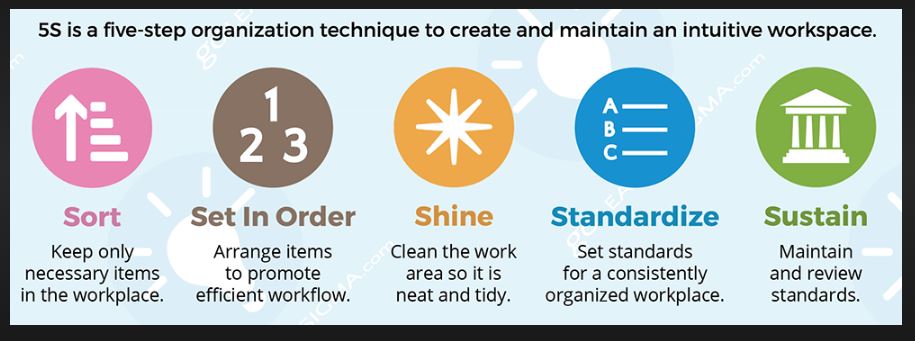

Over the last few weeks we have covered a number of topics related to Lean Construction Principles, the Daily Huddle, Pull Planning, Gemba Walks and the 5 S’s. Each of these play an important role in your Lean Tool Box. Today we are going to cover the 8 Wastes and how to help reduce their impact on your Project.

Over the years manufacturing has seen drastic improvement in the production of goods and this has lead to great improvements with in this industry. This same improvement has not been recognized within the construction industry. Those of us practicing Lean Construction are looking to change that, but to make this happen we must first identify the 8 Wastes. Traditionally this is associated with the amount of waste identified on the project. This can also be said as anything that is identified that does not add value to your project.

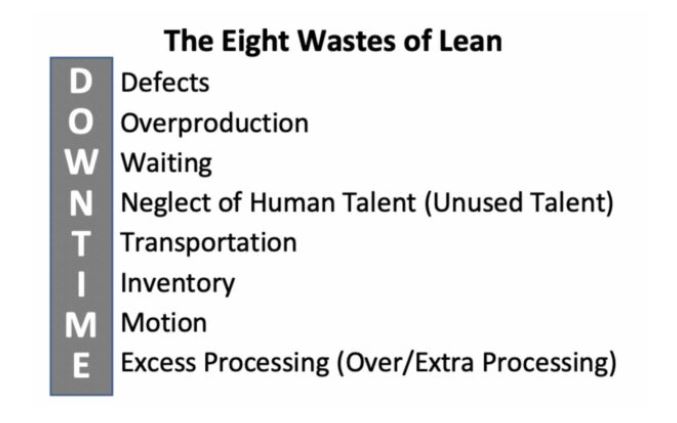

The 8 Wastes consist of Defects, Over Production, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion and Excess. Each of these have an impact on how your job runs and by being able to recognize their impact you will continue to sharpen your Lean Tools.

- Defects are anything that has been damaged and repaired, replaced or re-done. This includes materials that appear on a Punch List. This results in the re-work or scrapping of the work.

- Over production is building to soon, delivery of materials to the project before it is ready to be installed which causes double handling. And may lend to defects if the material is damaged while waiting to be installed. Just in time delivery has materials arriving on the project when it is ready to be installed.

- Waiting corresponds to crews waiting on materials or the completion of activities that need to be done prior to another activity happening. Like an RFI being answered. Project equipment like Cranes not being fully utilized is also an example of waiting waste. What we are striving for is continuous flow in people, equipment or materials.

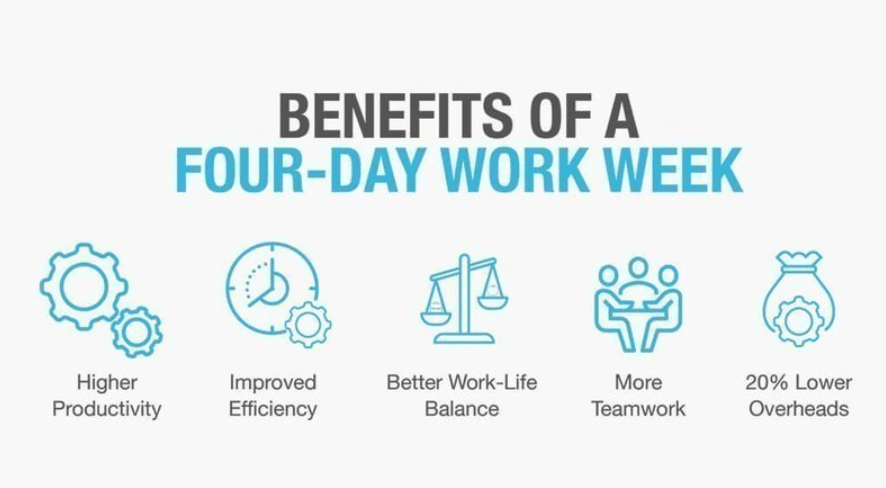

- Non-Utilized Talent is failing to make use of the skills or knowledge of your team. A decentralized command structure allows for the craftsmen responsible for producing the work to be more engaged in the process and use their knowledge to improve production.

- Transportation is the unnecessary movement of materials or equipment. This often occurs when materials are delivered to a project too soon and need to be moved from one location to another to facilitate work taking place in that area.

- Inventory is the over production of materials or equipment resulting in excess. This material is then needed to be stored in the yard or shipped back to the manufacturing facility where it was produced.

- Motion waste is identified as the extra steps the craftsmen will take to complete their work. Such as time searching for the correct material or the tools necessary to complete the job. This can also be identified as any lifting, reaching, bending and the excess movement necessary to install the materials.

- Excess is the over processing materials in the value chain which may cause double handling or transporting material back to the shop or manufacturer, this often creates storage costs.

These wastes are often identified with the acronym “DOWNTIME”

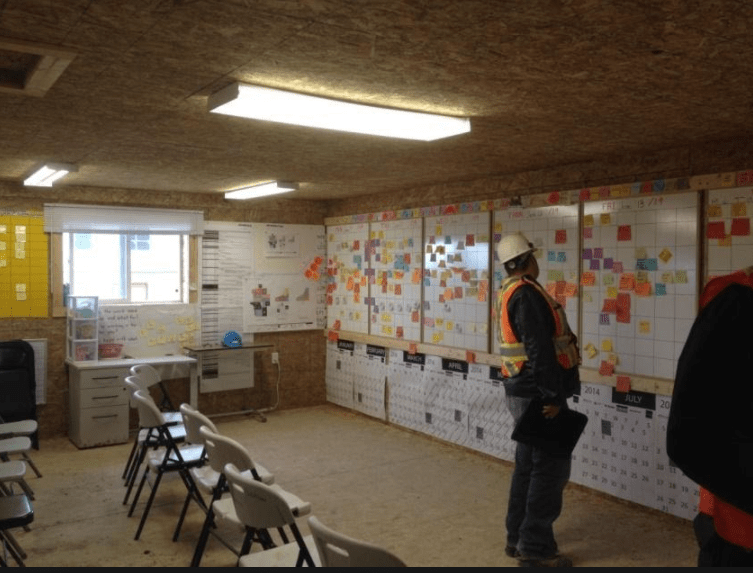

So how does one go about identifying these wastes? It can often be done with a Gemba walk, by having discussions with the suppliers/manufacturers or employees on the project. Once you understand where one of the 8 wastes is originating you can work to reduce or eliminate its impact on your project.

There is a great book written by Paul Akers ” 2 Second Lean” which goes into his company’s Lean Journey. It covers in detail their journey to reduce waste and their process for continual improvement. This book is readily available on their website and has been made available as a free download.

So the question is posed, how will you identify waste on your project, what will be done to help eliminate its effect and how will this effect project planning in the future?

For the last few weeks I have posted a number of articles related to Lean and my own Lean journey I hope these have provided you some additional tools for you and your team to use. If you are looking to see some of my past articles or would like to see me cover something else related to Lean please feel free to reach out to me here or on my blog www.construction-daily.com

J. Hughes

Superintendent