I have been considering the possibility of the 4 day work week in construction, is it possible and have you ever been successful in implementing it across a large commercial project. Lately I have been hearing how other industries have had some success in work from home and various forms of hybrid work. So in this post I would like to open up the conversation on how would we implement a similar opportunity for our project teams that manage work on the site.

What would this type of flexible working arrangement look like in construction? Generally speaking the projects I have been a part of typically work a Monday thru Friday schedule with Saturday being the makeup day for lost production or weather day. As the project pushes forward towards substantial completion and the schedules get tight more often than not we end up driving a 6 day schedule trying to make up time that may have been lost due to decisions being made slowly, materials being late or not having enough manpower to keep up with the schedule.

Generally our days start at 6:30 in the morning and we work our project teams until around 4 or 5. Understanding this could we set a standard to work 4/10’s and keep the project on track. Possibly using Friday as the makeup day. Most weeks this would ensure a 4 day work week and it would set a standard of allowing project teams having the entire weekend free.

There are already a number of trades working on the project that have implemented this successfully – I have seen our Elevator/Escalator crews manage this along with the Fire Protection contractors. I believe this allows them to be more productive each day. They set themselves up for this; their materials are ordered and available well in advance and delivered to the project in time to be installed. I believe this assists with the loss productivity daily by having to unroll and roll up your tools allowing for more effective daily production.

What would it take to ensure this, initially you would need to discuss and demonstrate to leadership and the owners on how this would be beneficial to the project. Then as the trade partners are being vetted and placed under contract the schedule would need to reflect this implementation. Material suppliers would need to be notified of the delivery schedule and inspectors would need to be aligned as well. The practical aspect would involve setting up the schedule to reflect the additional hours and the plan would need to show this to keep everyone on the same page.

Some of the challenges would involve the actual craft worker who would be called to make this happen and production cannot be slowed because of the additional hours each day. During the summer months where heat can play a serious role on our projects how do we keep the teams safe while working through the heat? At times we observe when the crafts are working additional hours each day they tend to tire and production slows. Delivery companies would need to be coordinated with to make sure materials are not being delivered when the site is closed. And daily how would we manage the change in time where we are coming to work and its still dark.

The benefits of a 4 day work week cannot be understated, more opportunity to spend time with your families, better rest and more time away from the project to clear your head. This forward look at the well being of our project teams would play out in a number of ways in both keeping valued employees from burning out and seeking employment elsewhere and could entice some prospective employees to join the team.

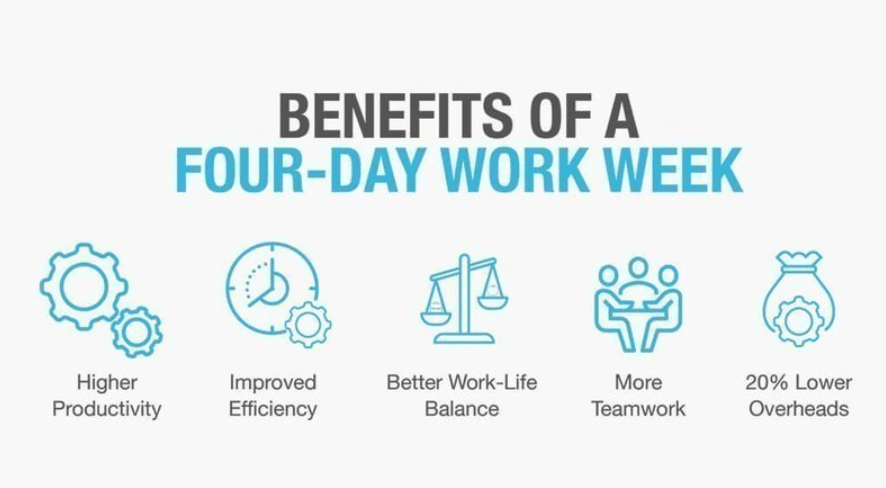

This practice is being review by companies large and small and there are stats to prove that companies could see as much as a 20% improvement in production not to mention the benefit of employee wellbeing and engagement. This concept is not new but not to long ago it would have been viewed negatively and you may have been considered a slacker for even considering it. But as this continues to gain momentum the question you may need to ask yourself will you continue to do it the way its always been done or will you look for ways to be innovative and demonstrate to your employees you really care about their time and more importantly their time away from the project.

So I am interested, is this something you have tried or are you currently implementing it and what is your take of the 4 day work week in construction?

We will continue to focus on Lean, Employee Well Being and Improved Productivity over the next few weeks and if you have any additional ideas or items you would like covered please let me know here or my page at Construction-Daily.com

Superintendent

J. Hughes

The 4 day work week is 4 – 8 hour days. You don’t get more time with family if you work the same number of hours. The productivity comes from more rest, not more hours on fewer days. People in the studies you mention get paid for 40 hours (M-F) but now work 32 instead. That’s the extra time with family part.

LikeLike

It depends, my typical workday starts at 6:30a and I rarely leave before 5:30p – I generally achieve the 40 hours work week in 4 days. As far as the trades go they are generally more productive as they roll out get everything going and start producing – you could potentially create 3 additional hours of productivity in the same 40 hours for them.

LikeLike