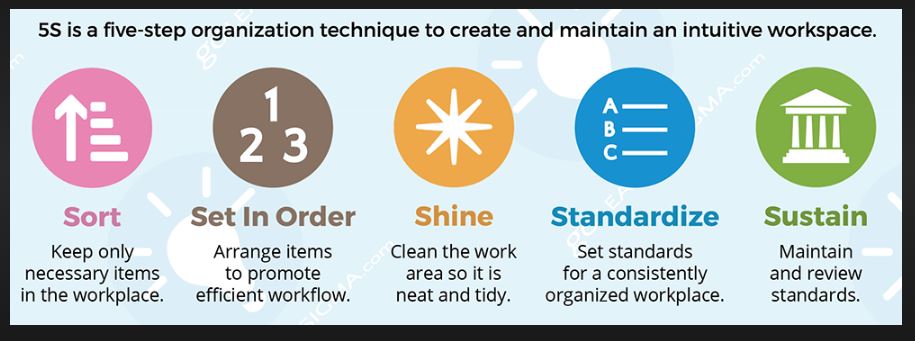

When we talk about Lean what key concepts come to mind, The Last Planner System, Pull Planning, Daily Huddles each of these have their role in your Lean Tool Box. But at the heart of Lean are the 5 S’s. Sort, Straighten, Shine, Standardize and Sustain. It is in these concepts we find the core principles of Lean Construction, the very basis of continuous improvement. At its core we should always be striving to get better and we do this by looking to eliminate waste in every step allowing each step we take to become more efficient.

Lean is continuously looking to improve Safety, Quality, Productivity and Schedule. Each of these are core concepts for Lean Project. By assessing the work as it’s being done, removing the unnecessary, organizing the work and tools logically, keeping the area clean at its essences you are in fact being Lean. By tolerating anything less the project and project team will not operate at its full potential. So how do we utilize the 5 S’s to strengthen these principles.

Lets go over and define each of these so we can better understand the 5 S’s.

- Sort – What is needed in the next few days and remove anything else as waste.

- Straighten – Everything has a place, keep it close and organized.

- Shine – Clean as you go as a daily practice.

- Standardize – A systems approach to improvement for every task.

- Sustain – Having a process in place to keep it going.

When implementing Lean on the project it is very important to discuss the expectations early and often, this needs to be discussed with the contractors while they are bidding on the project. Set the expectations of a organized well run project before they sign their subcontracts, spell out the expectations. When new employees are going through the project orientation process discuss how this will look in practice and as you are walking the project its what you tolerate not what you preach, substandard performance will not be tolerated.

Initially as contractors start work on the job they will push the envelope as to what will be accepted, consistency is key, ensuring from day one you keep to your word, everyone including your team will be held to this standard. Not just getting by but improving every day.

How does this happen in practice, materials will not be delivered to sit and wait for installation but will be delivered just in time – nothing hits the ground, everything is in racks and on wheels. The job will be kept clean as the work progresses, not a weekly composite crew but an expectation every crew cleans as they go as the task’s are being completed. Tasks will be reviewed for optimization and standards set to ensure its practice and discussions held looking for improvement.

So how will the 5 S’s benefit the project:

- Safer Work Environment

- Higher Quality

- Increased Productivity

- Lower Costs

- Greater Employee Satisfaction

- Customer Image

These concepts are intended as tools and tools are meant to be sharpened and this happens at your daily stand ups where you discuss material deliveries, as you walk the project and while you are talking with team members in the field. It is not a one and done application and for the 5 S’s to be beneficial to you and the project you must continue to utilized it to improve. It must become part of the project culture and collaborative in nature with your team and the teams that are working on the job. The trade partners should not feel if you are questioning them it is criticism but they should understand the project is looking to improve at every turn.

Now we have covered some basics, how do you expand on this, there are a great number of resources on the internet – Lean Construction Institute, The Lean Builder, and the Lean Construction Blog. Each of these provide great content and have many resources available, some paid and some for free.

Over the last few weeks I have posted a number articles on Lean, including Pull Planning, the Daily Huddle and how to perform a Gemba Walk, if you have any additional topics you would like to see covered let me know and I will try and help. If you would like to see any of my previous post they are available on my blog at www.construction-daily.com.

Once again thank you for joining me on my Lean Journey,

J. Hughes

Superintendent